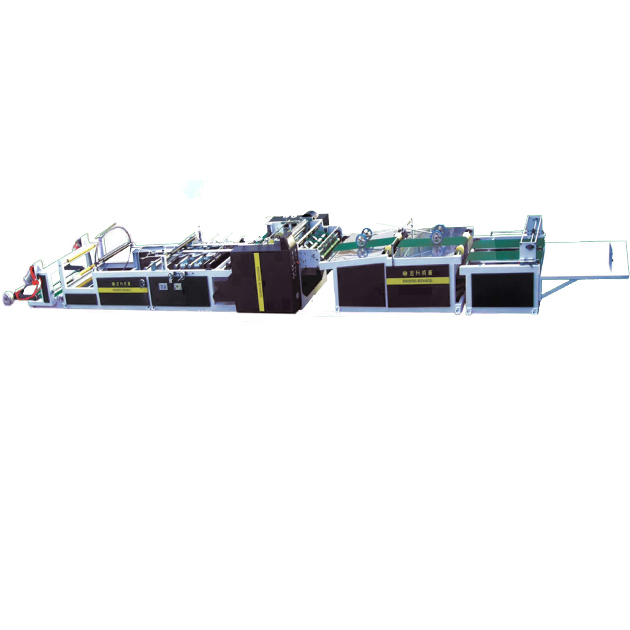

M Type Valve Bag Making Machine

- Proceeding shift, folding edge M, and rewinding again.

- Knitted mesh, laminating knitted mesh, BOPP compound knitted mesh, paper-plastic lamination knitted mesh and other wholly rolled materials;

- Applicable Substrates Materials: Knitted mesh, laminating knitted mesh, BOPP compound knitted mesh, paper-plastic lamination knitted mesh and other wholly rolled materials

Tips: Due to machine’s upgrade, machine’s configuration, colors, surface may different, supplier keep the rights to modify.

Machine's Feature

- Unwinding section

The automatic deviation-checking mechanism equipped with automatic tension control mechanism

- Forming section

Both the edge fold guide mechanism and the clamping roller traction mechanism can be adjusted flexibly to ensure the shift, the accuracy of the width of the bag after folding M side and the stability of margin folding forming. Multiple styles of M-edge models can be equipped in factory according to product requirements.

Machine's Parameter

| Model | MS-CB-700 |

| Line Speed | 20~120(m/min) |

| Depth of edge fold | 30-100mm |

| Roller Effective Length | 700mm |

| Max Dia Of Un/Rewinder | 1400mm |

| Un/Rewinder Paper Core Inner Dia | 3” |

| Installed Power | 10KW |

| Rated Voltage | 380-440VAC |

| Air Source Requirement | 0.5-0.6Mpa |

| Machine Weight | 8M*1.5M*1.5M |