Característica de la máquina

Rendimiento y características Se adopta una transmisión de rueda rodante con viga oscilante y mesa de tipo lata pequeña, lo que hace que su funcionamiento sea fácil y estable. El bloque deslizante y la varilla están climatizados, mientras que las piezas de desgaste se reducen. Se adopta una transmisión rodante en su totalidad, que no necesita lubricante.

Máquina's Específico:

It is configured with automatically stop detecting unit when meeting the situation of warp weft breaking.weft ending.The stoppage unit is sensitive and reliable It's an environmental product whose noise is not more than 80 dB(A). Low strength plastic yarn which is made from 100%, regenerated plastic can be adopted to weave It is high-efficient and cacrgycconomical.the highest rotation speed of the main motor can reach 180 r/min and the power is 1.5/2.2 kw which can save 10 thousand degree electricity compared with the traditional four shuttle circular loom whose power is 4 kw.

Parámetros de la máquina

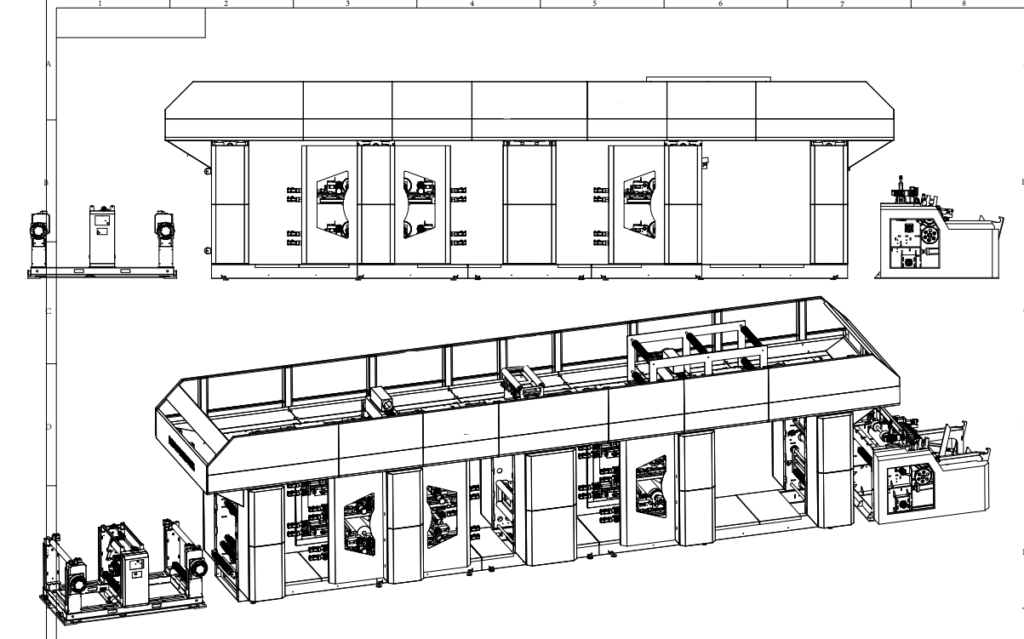

| Unwind | ||||||||

| 1. Magnetic powder: 10kg x2 | ||||||||

| 2. Inflatable shaft: φ75 x2 | ||||||||

| 3. Correction control equipment: stroke 200 | ||||||||

| 4. Tension control equipment (air) | ||||||||

| 5.Non-stop double-station unwinding | ||||||||

| Front and Rear Traction | ||||||||

| 1. Servo motor: 4.3kw x2 (Delta, Inovance, INVT) | ||||||||

| 2. Precise low-friction cylinder tension control x4 | ||||||||

| 3. Corona processor x1 (double-sided) | ||||||||

| 4. Automatic positioning and deviation correction, feeding | ||||||||

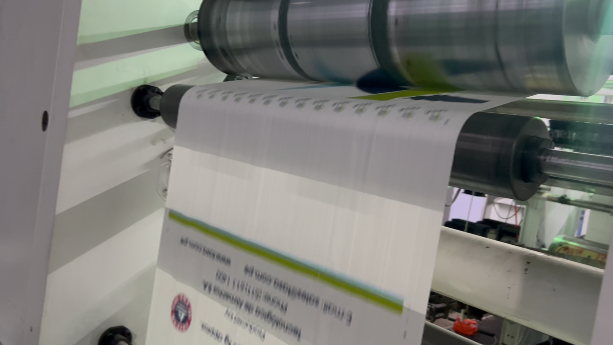

| Printing | ||||||||

| 1. Plate roller (chrome-plated) x6 (one for each color) | ||||||||

| 2. Printing roller x6 (one for each color) | ||||||||

| 3. Printing roller servo motor: 4.3kw x6 (Delta, Inovance, INVT) | ||||||||

| 4. Ceramic anilox roller x6 (one for each color) | ||||||||

| 5. Servo motor control (imprinting, point-to-point): 400w x32 (Delta, Inovance, INVT) | ||||||||

| 6. Ink cartridge (aluminum) x6 closed double scraper (one set for one color) | ||||||||

| 7. Ink distribution motor x6 (stop ink distribution, one for each color) | ||||||||

| 8. Color matching system (automatic, manual), CCD camera, self-developed patent | ||||||||

| 9. Still picture (camera x2, monitor) | ||||||||

| 10. Automatic deviation correction system x2 (one set for positive and one negative) | ||||||||

| 11. Built-in power distribution cabinet | ||||||||

| Water Cooling | ||||||||

| 1. Water cooling roller x2 | ||||||||

| 2. Fan 1.1kw x2 | ||||||||

| 3. Servo motor: 4.3kw x2 (Delta, Inovance, INVT) | ||||||||

| 4. Drying (UV lamp) | ||||||||

| Winding | ||||||||

| 1. Backrest winding (4.3wk servo motor) (Delta, Inovance, INVT) | ||||||||

| 2. Inflatable shaft φ75 x2 | ||||||||

| 3. Pneumatic blanking and pressing | ||||||||

| 4. Non-stop automatic roll changing and winding | ||||||||

| 5. Automatic cutting (700w servo motor control) |